Changdatong has reached a customized cooperation agreement on T-Key7800-64C with the world's top metallurgical equipment suppliers

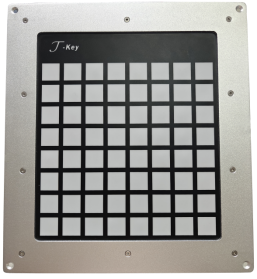

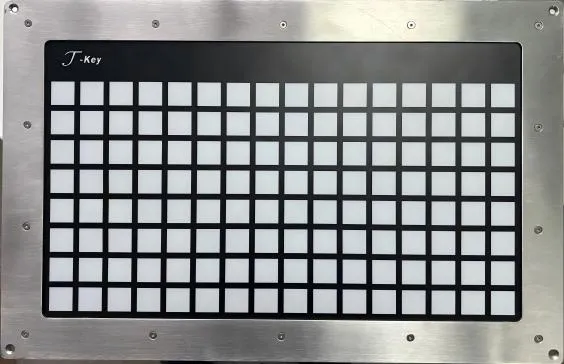

Tianjin Changdatong Technology Co., Ltd. has officially signed a cooperation agreement with a world-class metallurgical equipment supplier to customize the T-Key7800-64C industrial membrane keyboard for it. This cooperation is oriented towards the core demands of the customer's equipment. Through in-depth customized design, it achieves precise matching of the product with high-end metallurgical equipment, highlighting Changdatong's technical strength in the field of industrial control interface customization.

As a key piece of equipment in the long product production line, the operation interface of the long product rolling mill faces more stringent challenges:

Space is extremely restricted.

The control console of the long product rolling mill is integrated into the compact rolling line equipment. The highly integrated operation interface ensures full-function control such as the start and stop of the rolling mill, speed adjustment, and mode switching within a limited space.

The response to instructions is extremely strict

The production pace of long materials is fast. The rolling mill needs to frequently switch multiple parameters to match the processing requirements of long materials of different specifications. The response speed and accuracy of instructions directly affect the product quality, and higher requirements are put forward for the stability and sensitivity of the operation interface.

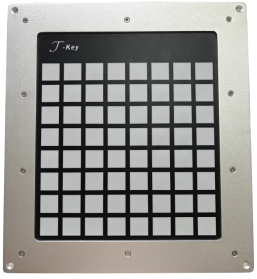

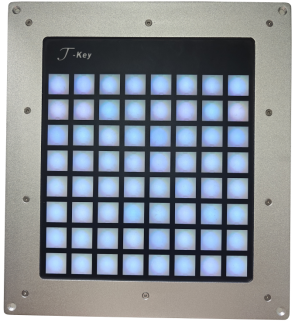

The T-Key7800-64C achieves complex control of the rolling mill in an extremely small space through a 64-key streamlined layout and 8 channels of optically isolated IO, precisely addressing the special challenges of long product rolling lines.

Hardcore performance: Deeply optimized for metallurgical scenarios

Compact body, powerful protection

Embedded installation design (standardized opening size) maximizes space savings in the control cabinet of the long product rolling mill.

With an IP54 protection rating, it can effectively resist the penetration of metal dust and the erosion of oil stains, thereby extending the service life of the equipment.

Anti-interference and stability upgrade

Relying on the photoelectric isolation technology that supports 20-30VDC signal isolation with 8 input/output channels, it can effectively suppress electromagnetic interference in the complex electrical environment of long material rolling lines.

The product has passed the CE certification and fully complies with international standards in terms of electromagnetic compatibility, safety performance, etc., providing dual guarantees for the stable operation of the rolling mill.

Durable and intelligent, reducing misoperation

Industrial-grade buttons have passed rigorous press tests, with a service life of up to 1 million hours for the buttons and 50,000 hours for the lights. They can withstand high-frequency operation requirements and ensure long-term reliability.

It adopts an RGB three-color light combination indication, allowing for free matching and combination of light colors according to the production line requirements of the enterprise. It visually presents the operating status of the equipment and significantly reduces the complexity of manual judgment.

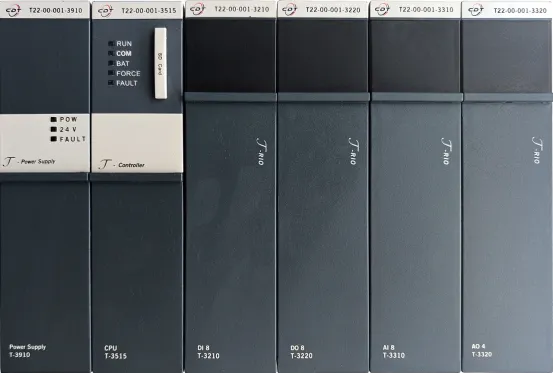

The system is highly compatible and adaptable

Supports the Profinet protocol, and in the Botu configuration software, it supports functions such as topology and diagnosis. It is compatible with Siemens PLC, achieving plug-and-play and reducing the debugging cost during equipment integration.

Our product series matrix comprehensively covers the demands of metallurgical customers

The T-Key7800-64C and T-Key7800-128C customized for the customer this time are important components of Changdatong's industrial membrane keyboard series products. In response to the diverse scenarios in the metallurgical industry, the company has currently established a full range of product layouts including 16-key, 32-key, 64-key and 128-key products, which can meet the differentiated demands of different metallurgical manufacturing processes in terms of control complexity and space requirements, and fully respond to customers' customized demands.

Win-win cooperation opens a new chapter

This cooperation not only provides a more suitable control interface solution for the customer's long steel rolling line, but also achieves a two-way value enhancement: for the customer, the customized design reduces the adaptation and adjustment costs during the integration of the rolling mill, and improves the convenience of operation and operational stability. For Changdatong, through in-depth cooperation with top enterprises, the feasibility of customized solutions for the full range of products has been further verified, and valuable experience has been accumulated for serving more metallurgical scenarios. In the future, both sides will deepen cooperation, promote the T-Key series of products to cover metallurgical production lines such as electric furnace steelmaking, hot rolling, cold rolling and long product rolling lines, and customize interaction solutions to adapt to the operation logic of each production line, helping metallurgical production lines accelerate their advancement towards intelligent and centralized control "dark factories".

In the future, Changdatong will continue to take customer needs as the core, relying on the customization capabilities of its full range of products, to provide more precise control interface solutions for the metallurgical industry, and promote industrial upgrading through technological customization.

Tianjin Changdatong Technology Co., LTD

Please first Loginlater ~